Farid Computrol discusses how Computrol continues to provide on-time contract manufacturing services by investing in versatile, high-speed manufacturing equipment and technology.

| Farid Anani, Manufacturing Manager at Computrol, Inc. |

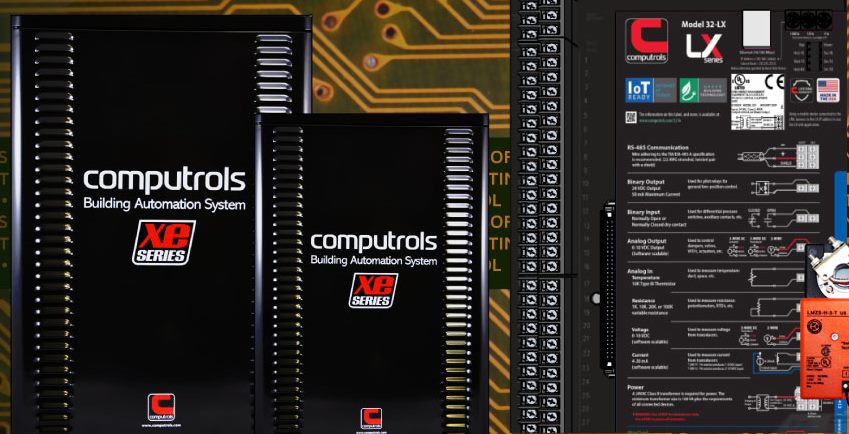

Founded in 1984, Computrol has a long history of providing electronics contract manufacturing services and support to blue-chip customers ranging from military and medical electronics to telecommunications and computer peripherals. Computrol continues to build on its core services and capabilities by investing in versatile, high-speed manufacturing equipment and technology, as well as continuing training programs for employees.

Farid Anani has held several positions in the CEM business throughout the past 20 years. His career started with Tandy Electronics Manufacturing Division in Salt Lake City, UT as a process engineer, then he was promoted to engineering manager and finally, he went on to become the operations manager. He became Circuit Technology’s vice president of manufacturing in 1993 and joined Computrol in 2000 as the manufacturing manager.

At Computrol, Farid leads the engineering and production groups. With his ability to solve technical problems and lead multi-disciplinary teams, Farid has championed several projects including Valor’s implementation, which has resulted in quality enhancement and increased reliability and profitability, further earning him the trust and respect of both colleagues and clients. He graduated from the South Dakota School of Mines and Technology with a Master’s of Science in Electrical Engineering in 1989 and from Boise State University with an MBA in 2006. We had a chance to speak with Farid to discuss Comptrol’s low-to-mid volume electronics manufacturing capabilities.

Q. Computrol boasts a multiple plant footprint with facilities in both Orem, Utah and Meridian, Idaho. How does this footprint help the company?

A. Our footprint helps the company in many ways, including the following:

- It allows us to broaden the geographical area of served markets. We have been able to do business with a wider range of customers and expand our customer base.

- It enables us to have more flexibility in terms of meeting production demands by sharing some work between plants.

- It has increased our technical knowledge database. Through daily interactions, our plants benefit from one another.

Q. How do your customers benefit from the multi-plant footprint?

A. The plants are designed to be as identical as possible with only slight differences. There are services we are now able to offer that a single plant cannot. For example, the Orem plant now offers cable and harness services to existing customers because the Meridian plant has that capability. At the same time, Meridian is able to compete for higher volume business because that is a capability that the Orem plant has.

Q. Computrol’s philosophy is that the people behind the company are a large part of what makes the company successful. Please describe your training programs and employee retention.

A. At Computrol we truly give employees a vested interest in the success of the company. This vested interest involves several incentive programs, rewards and employee benefit programs. Employees feel that their part of the job is to make their company successful. At Computrol, we call that “Spirit of Intrapreneurship”.

Q. You recently installed a PVA650 Robotic Dispenser and two KISS 103 Selective Solder Systems. How have you benefited from new installations?

A. The PVA650 is the first fully automated conformal coating and dispensing system at the Meridian plant. Orem already has two similar systems from PVA as well. With this system, we are able to achieve two main objectives: 1) Automated conformal coating dispensing with high repeatable precision and minimal masking prep work; 2) Adhesive and potting material dispensing in extremely tight geometries. Both capabilities give us a technical competitive edge while reducing production cycle time.

The two KISS 103 selective soldering systems were installed in Meridian to handle larger board formats up to 18 x 24″. The systems can handle smaller boards as well. Similarly, the systems allow us to reduce cycle times while increasing quality and repeatability. This allows us to rely less on hand soldering because masking and hand soldering the boards are no longer required. The production of boards that required skilled employees to hand solder/fountain can now be run on the KISS 103, allowing them to focus on other higher level work. We have experienced significant improvements in time standards and consistent quality of boards moved to the KISS 103.

Q. Have you added any other new equipment or completed any facility upgrades this year?

A. Recently, we added a new Heller Mark III reflow oven, replacing an older Conceptronics oven. Computrol is constantly trying to stay technologically current by replacing ageing machines.

The Mark III is the new generation of the 1809 model with 18 independent heating zones capable of reaching 350oC. With precision temperature control, this is the ideal oven for larger mass PCBs requiring lead-free solder reflow.

Q. What are some of the common assembly challenges your customers face?

A. We have seen an increase in layer count, which poses new challenges for all soldering processes, including SMT and through-hole.

Due to restricted geometries, PCB layouts constantly are pushing the limits of what is optimum. It seems everything is operating close to the edge of the process window, rather than in the middle, allowing consistency and repeatability.

Q. Please offer tips on how customers can cope with shrinking parts and PCB sizes and increased layer count, and explain how your electronics manufacturing capabilities can help.

A. Over the past couple of years, we have invested heavily in state-of-the-art equipment designed to deal with PCB size, layer count and component size challenges. The process does not really change much — only the operating parameters. They need to be dialled in accurately with minimal room for fluctuation. Ten years ago, you could get by with three different reflow profiles (small, medium and large). Today, every assembly has to be profiled and dialled in uniquely.

A. Other capabilities we are able to offer include in-house design modifications. Also, we have partnered with a couple of other reputable companies that help us with design and PCB layout services. Often, our customers’ engineering departments are stretched dealing with their next-generation of products and do not have the bandwidth to deal with current product design enhancements. This is where we can provide a great deal of value.

As far as test development goes, we have the capability to develop flying probe tests in-house, as well as boundary scan and JTAG tests. We have invested in the GOEPEL software for that.

Additionally, we have the ability to design customized functional testing using the LABVIEW suite.

For more information visit Contact Us.