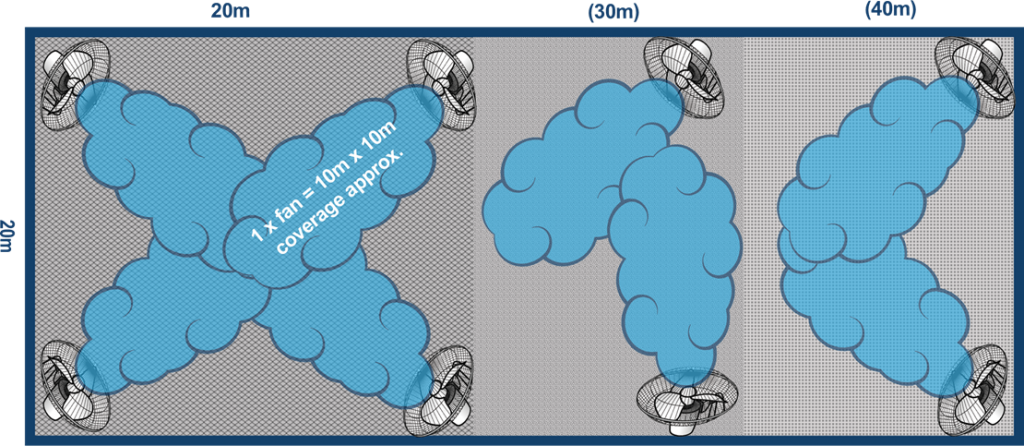

factory fan layout

9 factory cooling

How does it work?

Normal mains water is pressurized to 1,000PSI or 70 BAR by the Ozmist pump module. The high-pressure water is fed through a high-pressure nylon tube to each fan position. A brass compression fitting is cut into the tubing at each fan location and a Synflex hose connects between the fitting and stainless steel misting rich which is attached to the face of a high-velocity fan. A standard misting ring has 6 specially designed nozzles that atomize the water into millions of tiny droplets (one-tenth the thickness of a human hair). The air from the fan throws the mist over a great distance (up to 12 meters). As the droplets of water hit the hot atmosphere they use up the heat energy in the air as they evaporate. Each gram of water removes around 540 calories of heat energy, thus cooling the immediate area. The OZmist system is not adversely affected by large access doors being left open, unlike evaporative air conditioners which rely on positive air pressure to work efficiently. Roof penetrations are not required and servicing is all done within the building, avoiding roof work. Only cooling workstations and not the whole building can reduce the purchase cost of a suitable air conditioning system by tens of thousands of dollars as one Ozmist pump module can run multiple misting fans, up to 23 on the largest pump module.

Factory and workshop cooling systems

Static misting lines can also be used to cool large areas. Misting lines are installed above the factory floor. Nozzle fittings and nozzles are inserted into the tubing predetermined spacing. Lines are clipped to a 3mm stainless steel cable that is attached to the building structure and tensioned. Static lines are ideal when used in “open plan” areas that do not have support posts for fans. Both systems offer an effective way of combating the extreme heat in the workplace.

Why Workplace Cooling is so important:

- Effective Temperature 25C 30C 35C 40C 45C

- Production Losses 9% 18% 27% 36% 54%

- Increased likelihood of Accidents 20% 42% 65% …… ……